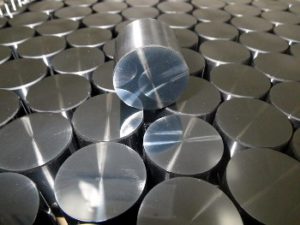

The new equipment will enable Schaeffler UK to produce superior quality mechanical tappets and other automotive engine components. The specialist machines provide an extremely hard, multi-layer coating, which minimises friction between mating components in the engine, resulting in lower fuel consumption and reduced CO2 emissions.

“This significant investment in new plant and machinery represents a tremendous shift in the way this factory will produce automotive components in the future,” said Roger Evans MBE, Plant Director at Schaeffler UK. “Without doubt, this investment is the single most important investment in this factory’s history. By embracing these advanced coating and deep drawing technologies, we will be able to produce new superior quality components that meet the specific needs of our automotive customer base, which will help safeguard the long term future of this factory.”

The new investment was supported by the Welsh government. Business Minister Edwina Hart added, “In these challenging trading conditions, it is vital that businesses remain ahead of the game – this investment will enable Schaeffler to remain highly competitive within a global market and I am pleased it has been supported by the Welsh government.”

The Schaeffler Group and its brands INA, LuK and FAG is a renowned supplier to the automotive industry as well as a leading manufacturer of rolling bearings worldwide. For more information about Schaeffler UK visit www.schaeffler.co.uk.

You can find out more about UK automotive manufacturing by downloading SMMT Motor Industry Facts 2011.