To date, that success has been built primarily on the internal combustion engine. Over the next decade or so, that expertise will reduce in importance. The UK will end the sale of new pure petrol and diesel cars and vans in 2030. The EU, our largest export market, will do the same by 2035. New HGVs will be zero emission by 2040. Other markets will follow. The transformation of our industry will be wholesale, rapid – and highly competitive.

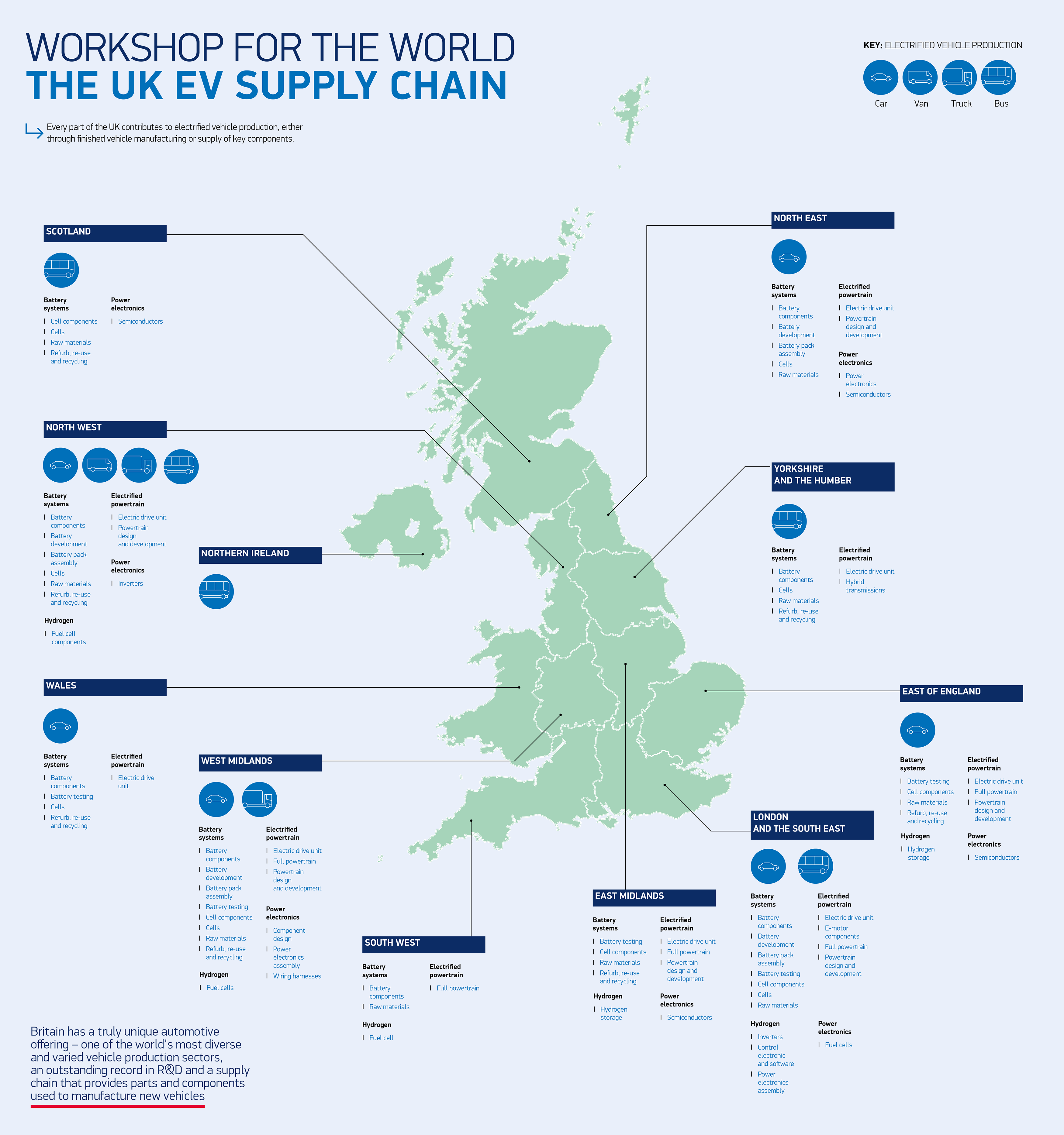

The UK is already a significant producer of battery electric and electrified vehicles, manufacturing zero emission cars, vans, buses and trucks. Underpinning vehicle production across the UK is an equally diverse supply chain, one which must also make the switch.

Britain has a foundational EV supply chain, one which has been mapped for the first time in SMMT’s new EV Supply Chain Directory. This shows that the UK already produced almost every component required to manufacture zero emission vehicles in some capacity: batteries, power electronics, hydrogen fuel cells, everything from anodes to graphene to silicon carbide wafers, are already made here.

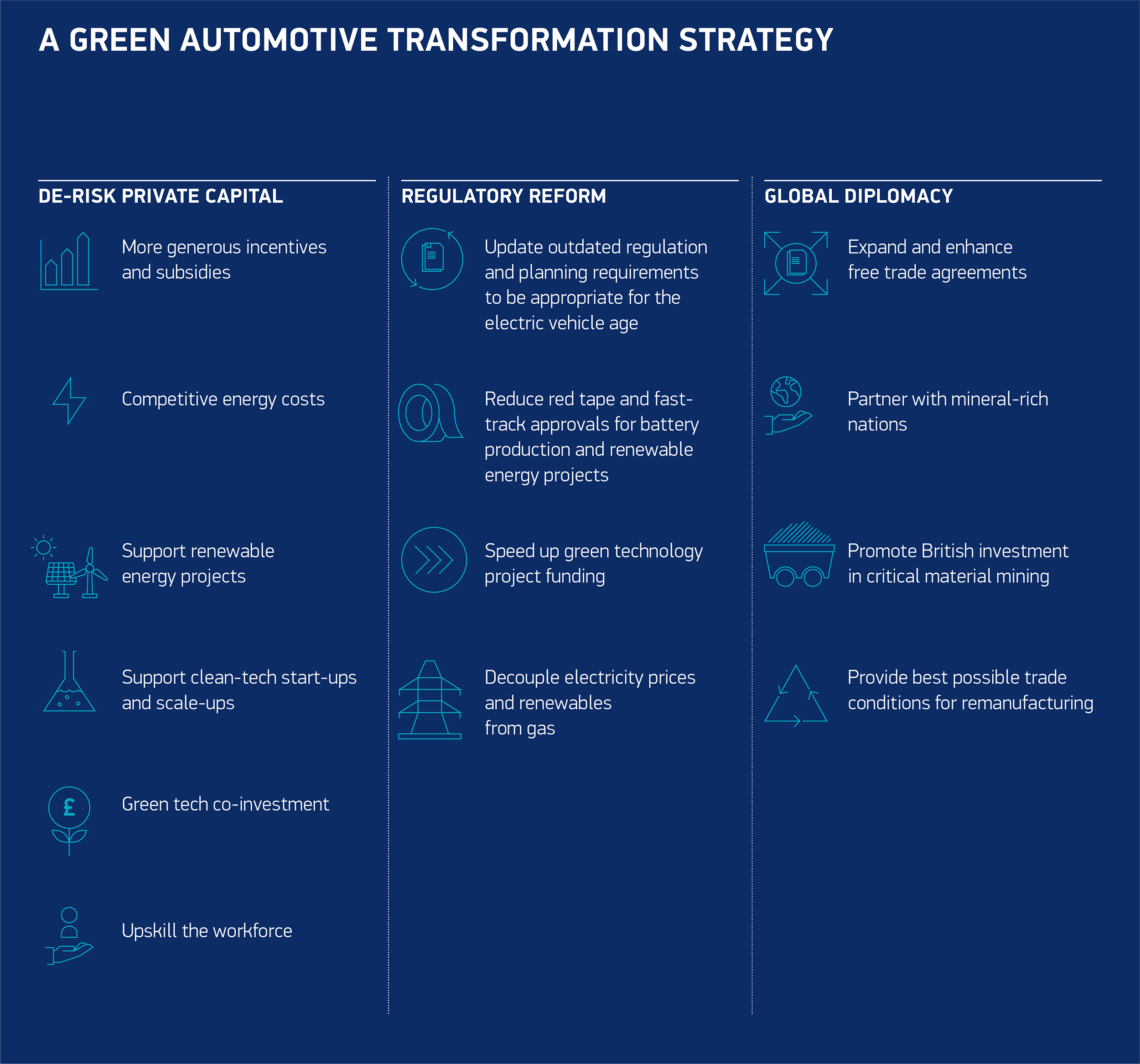

This report explores the great achievements and potential within our zero emission supply chain and sets out a blueprint for a Green Automotive Transition (GreAT) strategy to anchor future vehicle production in the UK.

Britain is a global leader in the decarbonisation of the vehicle market. But our aspiration must be broader. We must also be a leader in zero emission vehicle production, supported by a world class supply chain that acts as a workshop for new technologies delivered by a UK industry to a global market.