Over the next two weeks, the footballers of Mexico and Brazil will be facing one another in the group stages of the World Cup. While few are expecting Mexico to triumph in that encounter, the contest for the title of leading automotive producer in Latin America is much closer.

Currently, Brazil has a narrow lead, achieving seventh spot in the global league table for 2013, with a total production of 3.75 million vehicles. Mexico was one place, and approximately 700,000 units, behind. However, with Mexican manufacturing (led by the motor industry) consistently out-performing its Brazilian rival over the last two years, and with $10 billion of new automotive investment expected to flow into Mexico by the end of 2015, the positions may well be reversed.

Mexico is also out-stripping its NAFTA partners – particularly Canada – and is predicted to account for 25% of all automotive production within the free trade area by 2020.

Two key factors that have underpinned Mexico’s success in attracting investment from both VM’s and Tier 1 suppliers is a competitively-priced and increasingly well-skilled labour force, and a wide range of free trade agreements. With hourly rates for a production engineer of between $6.50 – $8.00 (and general workers earning as little as $3.00 per hour), Mexico has a significant – and long-standing – attraction as a manufacturing location within NAFTA. Its network of free trade agreements is the widest in the world – 44 international partners (including the EU) and still counting.

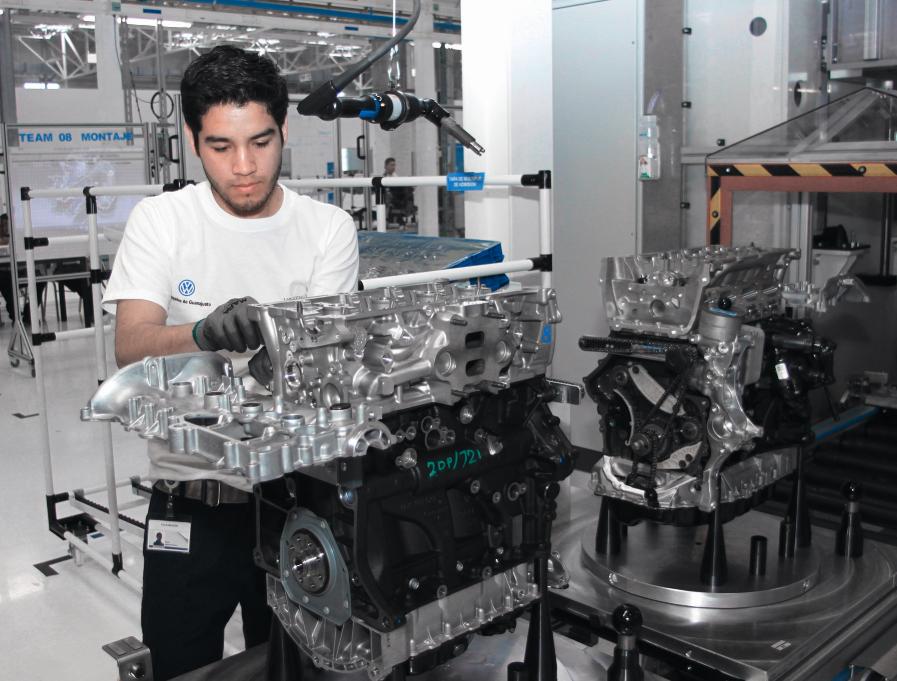

VW produces 330,000 engines a year in Mexico, plus the Beetle and Golf

There are also strong indications that the new government is serious about achieving further economic reform and business liberalisation. For example, the cross-party “Pact for Mexico” seeks to break open the energy market to competition, with the opportunity for further cost reductions for manufacturing industry.

Mexico’s automotive Achilles’ heel has long been the size of the local vehicle market, with sales falling short of the levels that might be expected in the world’s 11th most populous country. However, recent trends have been encouraging – car sales topped the one million mark in both 2012 and 2013, and further modest growth was recorded for the first quarter of this year.

Another challenge facing the auto sector in Mexico is to grow the production volumes and capabilities of second- and third-tier suppliers to keep pace with the expansion at the top of the automotive pyramid. This is an area where there are good opportunities for UK companies. There is an immediate demand for – amongst other components – forgings, castings, plastic injection mouldings, fasteners and electrical parts. And, of course, companies with a manufacturing base in Mexico can supply the whole NAFTA region, and beyond, without paying any customs duties.

While Brazil is playing a defensive game in the automotive sector, with its domestic industry and market protected behind high tariff walls, Mexico is taking a more expansive, outward-looking approach. Whatever the outcome in the Estadio Castelao on 17 June, Mexico’s auto industry seems certain to be a premier league player for many years to come.