The automotive industry is rapidly evolving in response to its role in addressing climate change, improving local air quality and ensuring resource preservation. Great progress has been made in all areas of vehicle lifecycle, but as we work towards net zero, the scale of the challenge cannot be underestimated. Close cooperation between industry, government and all stakeholders is needed to ensure the right policy framework and effective incentives are in place for industry to fulfil its potential and achieve shared goals.

Business energy

In automotive manufacturing, energy is typically the second largest variable cost, after labour, and is key to the competitiveness of UK manufacturing plants. The industry has invested heavily in reducing energy consumption over the years – with energy per vehicle produced down -43.3% over the past 20 years, delivering a -23% reduction in 2017/18 versus 2008 in the Climate Change Agreements (CCA) and a -25% reduction in EU Emissions Trading Scheme (ETS) emissions in 2019 versus 2013. However, the effects of Covid-19 are quickly unravelling short-term energy efficiency ambitions and will significantly constrain investment opportunities ahead.

Transport decarbonisation plan

In March 2020, government published Decarbonising Transport: Setting the Challenge, which outlines a coordinated, cross-modal plan to decarbonise all transport

in the UK. The Transport Decarbonisation Plan (TDP), which will be published later in 2020, will outline what is needed from all key actors to deliver a net-zero transport sector by 2050. The TDP will look at in-use GHG emissions. Emissions from power generation and distribution for transport are outside the scope of the plan, as they are covered in other government strategies. The Setting the Challenge document sets out six key strategic priority areas on which the final TDP will focus.

CO2

Industry shares government’s vision of a zero emission future and is spending billions developing the latest low and zero emission technologies to suit all driving needs, as well as implementing efficiencies across the manufacturing process. However, this requires a holistic approach as well as significant support from government to achieve the switch to ultra-low and zero emission vehicles, increase the development of renewable energy sources, plus funding for research to deliver zero emission manufacturing.

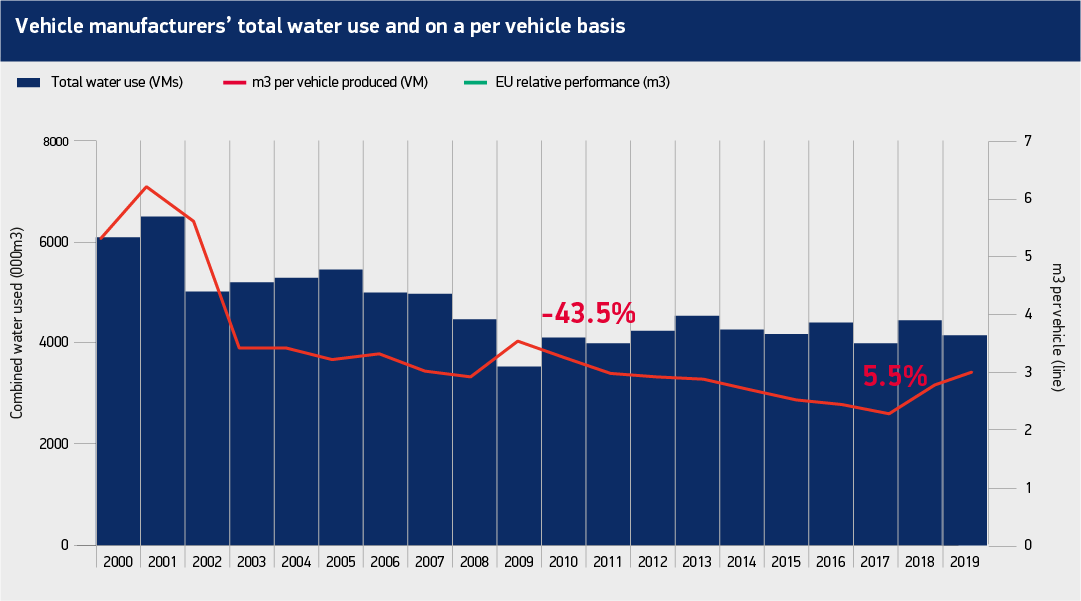

Water

Since 2000, long-term investments in water-efficient technologies and gradual adjustment of procedures have made it possible to reduce water use per vehicle by 43.5% and absolute volumes by 20.6%.

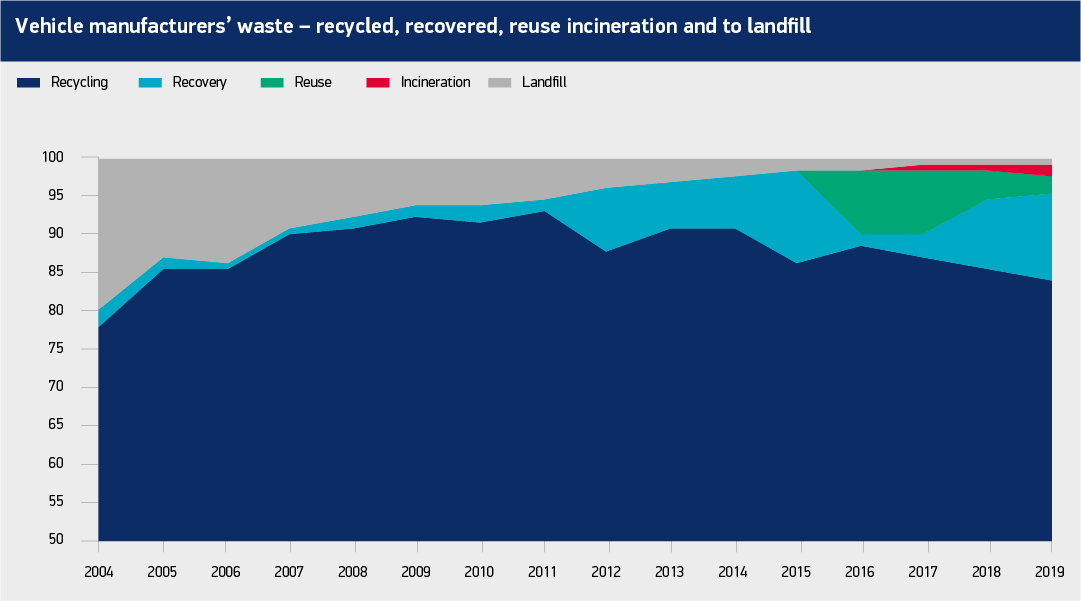

Waste

The automotive sector is a highly competitive industry, with ever increasing efficiency and cost reductions, meaning waste is now almost completely eliminated.

At the design stage, it is ensured that at least 95% of each vehicle by weight can be recycled and recovered at the end of its life. High quality standards of materials and production processes ensure that vehicles are long lasting, durable and repairable. Moreover, energy usage and related emissions at the production stage are kept to a minimum to reduce costs as well as carbon footprint.

Volatile Organic Compounds (VOCs)

The industry recognises the importance of reducing VOC emissions from its painting operations as one of the key environmental impacts of vehicle manufacturing. Consequently, the sector has invested heavily in painting equipment and improved its own processes, where possible going above and beyond the legal requirements. Since 1999, VOCs from painting dropped by -39.2% for cars and by -29.7% for vans.